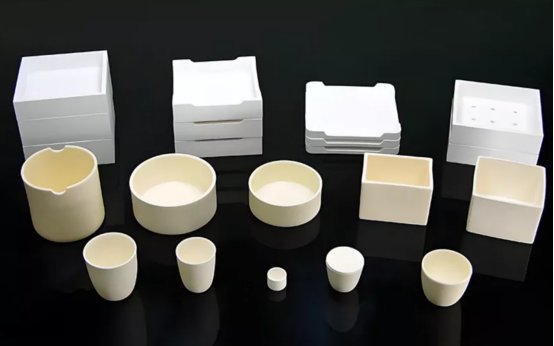

As an important part of chemical equipment, the crucible is a container for melting and refining metal liquids and heating solid-liquid reactions. It is the basis for the smooth progress of chemical reactions. Crucibles were originally made from clay, and one of the earliest uses of platinum was in the making of crucibles. As preparation techniques have evolved, crucibles can now be composed of any material capable of melting or changing their contents.

There are many types, models and specifications of crucibles, which can be selected at will. They have strong applicability and can ensure the purity of the melt. Ceramic crucible is an important part of the crucible. Ceramic crucibles can be divided into quartz crucibles, corundum crucibles, boron nitride crucibles, zirconia crucibles, etc. according to their raw materials. They are used in different occasions according to their different properties.

Quartz ceramic crucible (silica content ≥99.9%)

Quartz ceramic crucible is a ceramic crucible made of high-purity fused quartz. It has the characteristics of fine structure, low thermal conductivity, small thermal expansion coefficient, good thermal shock stability, good electrical properties, and good chemical resistance. It is widely used in glass deep processing industry, metallurgical industry, electronic industry, chemical industry, aerospace and other fields. Generally speaking, the shapes of quartz ceramic crucibles are mainly square and cylindrical.

Corundum (alumina) crucible

Corundum crucible, officially known as alumina crucible, when the alumina content exceeds 95%, it is usually called corundum crucible. Corundum crucible is strong and resistant to melting, high temperature, acid and alkali, cold and extreme heat, and chemical corrosion. It is suitable for melting samples of weakly alkaline substances such as Na2CO3 without water, but is not suitable for melting samples with water. Alumina crucibles are available in a variety of sizes and shapes depending on the application conditions.

Boron nitride crucible

Commonly used boron nitride types include cubic boron nitride (C-BN) and pyrolytic boron nitride (P-BN). Boron nitride crucibles are usually composed of P-BN. P-BN ceramic has good heat resistance, thermal stability, thermal conductivity, and high-temperature dielectric strength, making it an ideal heat dissipation material and high-temperature insulation material. P-BN crucible is often used to smelt metals and semiconductors, and its temperature can be as high as 1800 degrees in vacuum.

Zirconia crucible

Zirconia has a higher melting point than zirconium and is one of the most refractory materials in nature. Even if heated to 1900°C, zirconia will not react with molten aluminum, iron, nickel and platinum metals, silicates and acid slag, so the zirconia crucible can successfully smelt precious metals such as platinum, palladium, ruthenium and cesium. and its alloys.

Yttrium oxide crucible

Yttrium oxide ceramic is a high-performance ceramic with excellent heat resistance, corrosion resistance and high temperature stability. The melting point of yttrium oxide is greater than 2400°C, and it is difficult to react with some active metals (such as Ti, Al, Hf, Nb, etc.) at high temperatures. This crucible has the potential to melt Ti and Ti alloys, or any oxygen sensitive melting process. However, yttrium oxide has a high melting point and is difficult to process. Because yttrium oxide itself is very brittle, the crucible may crack if heated or cooled too quickly.